Safety & Occupational Footwear Explained

Legislation

The Health and Safety Law which regulates the PPE regulation 2016, states that it is the responsibility of the employer to ensure their employees are properly equipped for the work they undertake. This essentially means that if there is deemed to be a risk in the workplace, then the appropriate PPE should be used. It may be that is risk assessment is required to identify the required level of protection.

Standard

There are three main areas of classification for work and safety footwear, each with a corresponding ISO number;

- ISO 20347:2012 – PPE: Occupational Footwear – specifies basic and additional requirements for protective footwear used for general purpose.

- ISO 20345:2011 – PPE: Safety Footwear – specifies basic and additional requirements for safety footwear used for general purpose.

- ISO 20346:2014 – PPE: Protective Footwear – specifies basic and additional requirements for protective footwear used for general purpose.

Occupational footwear (ISO 20347:2012) has no requirement for a safety toecap. Both the Safety footwear and protective footwear classifications have a requirement for a safety toecap, the main difference between the two is requirement for the level of impact resistance in joules.

In an environment where the risks are deemed to be slipping with no mechanical or impact risks such as a hospital operating theatre then the occupational footwear classification level would be appropriate. In an environment where there are high mechanical risks such as construction or manufacturing a safety or protective level would be appropriate with additional requirements depending on the level of risk.

In addition to the specification included with each classification; special risks are covered by complementary job-related standards, such as footwear for firefighters, electrical insulating footwear and footwear protecting against chain saw injuries, chemicals and molten metal splash. Therefore, anybody issuing footwear needs to ensure it meets at least one of the above standards, and that they are appropriate for the environment and conditions.

The table below gives further details on each standard, together with the definitions set out in the ISO documentation:

| Standard: | Covering: | Official ISO Definition: |

| ISO 20347:2012 | Personal Protective Equipment – Occupational Footwear | Specifies basic and additional (optional) requirements for occupational footwear that is not exposed to any mechanical risks (impact or compression).

NB: Special risks are covered by complementary job-related standards (e.g. footwear for firefighters, electrical insulating footwear, protection against chain saw injuries, protection against chemicals and against molten metal splash, protection for motorcycle riders). |

| ISO 20345:2011

| Personal Protective Equipment – Safety Footwear | Specifies basic and additional (optional) requirements for safety footwear used for general purpose. It includes, for example, mechanical risks, slip resistance, thermal risks, ergonomic behaviour.

NB: Special risks are covered by complementary job-related standards (e.g. footwear for firefighters, electrical insulating footwear, protection against chain saw injuries, protection against chemicals and molten metal splash, protection for motorcycle riders). |

| ISO 20346:2014 | Personal Protective Equipment – Protective Footwear | Specifies basic and additional (optional) requirements for protective footwear used for general purposes. It includes, for example, mechanical risks, slip resistance, thermal risks, and ergonomic behaviour.

NB: Special risks are covered by complementary job-related standards (e.g. footwear for firefighters, electrical insulating footwear, protection against chain saw injuries, protection against chemicals and molten metal splash, protection for motorcycle riders). |

Footwear is split into two classes; Class 1 relates to footwear constructed from leather and other materials, but not rubber and polymers, whereas Class 2 relates to footwear constructed in one piece and includes moulded shoes and boots made from rubber and polymers.

The classifications within each of these footwear standards range from ‘B’ for basic, 1, 2 or 3 for class 1, and B, 4 or 5 for class 2 this is illustrated in the table below.

These standards are under regular review.

| Requirements footwear Class 1

(leather or other materials except rubber & polymers) | ISO 20345:2011

Safety Footwear | ISO 20346:2011

Protective Footwear | ISO 20347:2012

Occupational Footwear |

| Basic requirements for shoes and impact resistance of toecaps | SB

200 Joule | PB

100 Joule | OB

No requirement |

| Additional requirements:

· Closed heel · Antistatic · Energy absorption around the heel |

S1 |

P1 |

O1 + fuel resistant sole |

| Additional requirements, as above plus:

· Water penetration · Water absorption

|

S2 |

P2 |

O2 |

| Additional requirements, as above plus:

· Penetration resistance · Cleated sole

|

S3 |

P3 |

O3 |

| Requirements footwear Class 2

(manufactured in one-piece e.g. rubber & polymers) | ISO 20345:2011

Safety Footwear | ISO 20346:2011

Protective Footwear | ISO 20347:2012

Occupational Footwear |

| Basic requirements for shoes and impact resistance of toecaps | SB

200 Joule | PB

100 Joule | OB

No requirement |

| Additional requirements:

· Antistatic · Energy absorption around the heel |

S4

|

P4

|

O4

|

| Additional requirements, as above plus:

· Penetration resistance · Cleated outsole

|

S5 |

P5 |

O5 |

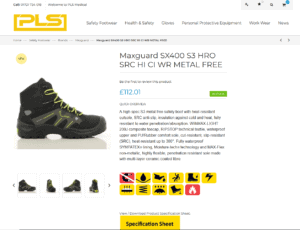

You may have noticed other letters accompanying the classifications above such as HRO. These codes relate to additional safety properties such as outsole resistance to hot contact (HRO). These abbreviations are detailed in the table below:

| Additional requirements for special applications | |

| Abbreviation: | Risk covered: |

| P | Penetration resistance |

| C | Conductive |

| A | Antistatic |

| I | Electrically Insulating |

| E | Energy-absorbing seat region |

| HI | Insulating against heat |

| CI | Insulating against cold |

| WRU | Water-resistant upper only |

| CR | Cut resistant upper |

| HRO | Outsole resistant to hot contact |

| WR | Whole footwear resistant to water penetration/absorption |

| M | Metatarsal protection |

| AN | Ankle protection |

| FO | Fuel oil resistant outsole |

| ESD | Electrostatic |

| SRA | *Slip resistance tested on ceramic surface with “soap” |

| SRB | *Slip resistance tested on steel with glycerol |

| SRC | *Slip resistance tested on both of the above |

*Click here for further information on slip-resistance ratings

Many of the above requirements and their abbreviations are also represented by symbols.

The above information is very useful in picking the correct safety footwear for the job. If for example, you are comparing an S1P safety boot to an S3, using the information above, you can see that the differences would be as follows:

The S1P offers the following protection:

- 200 joule toecap protection

- closed heel

- antistatic

- energy absorption around the heel

- penetration resistance (P)

And the S3 offers:

- 200 joule toecap protection

- closed heel

- antistatic

- energy absorption around the heel

- water penetration

- water absorption

- penetration resistance

- cleated sole

There are further requirements for specialist protection such as foundry work, chainsaw protection and firefighting requirements, further information on these can be found on the HSE website.

As occupational, protective and safety footwear must meet or exceed the above standards there are product specification or data sheets available for each product, as well as test certification. You can compare the product data to help choose the best product for your requirements.

If you would like further information on safety footwear or any particular product, please contact [email protected]

Would you like to know about professional footwear more before making a choice? You may find one of the following blog articles useful:

What are the best professional shoes for your needs? Click here to read our ‘What are the best nursing shoes for you?’ blog to find out more.

What makes safety & occupational footwear different from regular shoes? Click here to read our ‘Safety & Occupational Footwear Explained’ blog to find out more.

Why is slip-resistance important? Click here to read our ‘Slip Resistance Explained’ blog to find out more.

Do you need Anti-static or ESD? Click here to read our ‘Anti-static & ESD Explained’ blog to find out more.

Find us on social media here: